Tel: +86-531-88917773 E-Mail: eaststar@public.jn.sd.cn

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

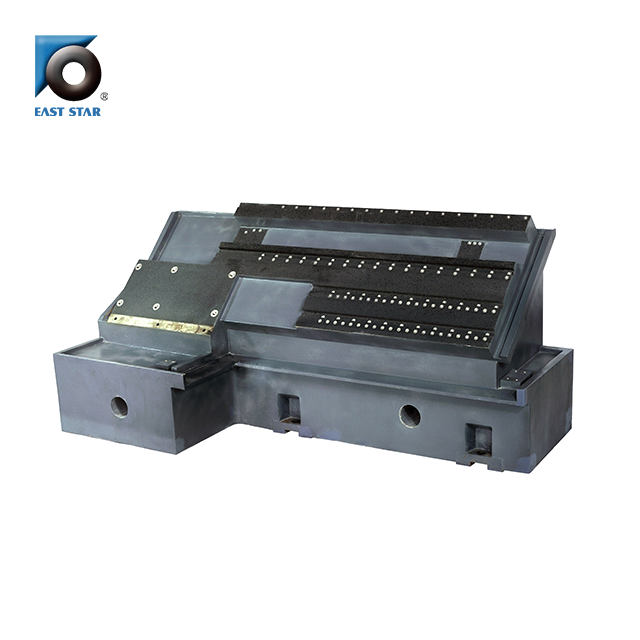

The verticality, flatness and parallelism of mold assembly can reach 0.1mm, and the surface grinding of mineral materials or embedded steel plate milling and drilling accuracy can reach 0.005mm. In the production of series parts, precision surface castings produced by instrumentation, injection molding and other processes can greatly reduce production costs.

Ultra-high performance mineral materials have high heat capacity and a thermal expansion coefficient similar to that of iron, which reduces the thermal impact on machine tools and is conducive to the effective combination of ultra-high strength materials with other components.

| Parameter | Value |

| Thermal Conductivity | 2.7 W/(m*k) |

| Specific Heat Capacity | 1050 J/(kg*k) |

Strong vibration damping performance:

Mineral castings have better vibration damping performance than steel and cast iron, and can effectively absorb and reduce external vibrations.

Good thermal stability:

Machine tools made of mineral castings have high specific heat capacity and low thermal conductivity, ensuring stability.

Self-compacting performance:

The high fluidity of the bonding material gives mineral castings excellent self-compacting properties.

Strong formability:

Mineral materials can be cast into complex shapes and structures, and have good forming capabilities.

Corrosion resistance:

The casting has a dense structure, low permeability, and excellent corrosion resistance.

Energy saving and environmental protection:

Mineral castings do not require further processing after molding, which shortens the production time.

Short delivery cycle to quickly meet customer needs.

Precision manufacturing:

The verticality, flatness and parallelism of mold assembly can reach 0.1mm.

Post-processing such as surface grinding or steel plate milling/drilling can achieve an accuracy of 0.005mm.

Cost-effective production:

The use of instrumentation and injection molding processes in the production of precision castings can significantly reduce production costs.

Thermal stability:

High-performance mineral materials have high heat capacities.

Their coefficient of thermal expansion is similar to that of cast iron, reducing the thermal impact on machine tools.

Effective integration:

The thermal properties of mineral castings enable better integration with ultra-high-strength materials and other components.

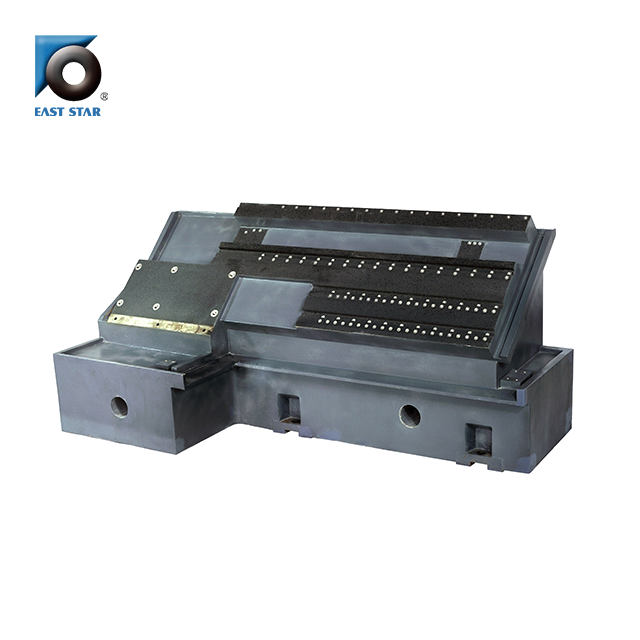

The verticality, flatness and parallelism of mold assembly can reach 0.1mm, and the surface grinding of mineral materials or embedded steel plate milling and drilling accuracy can reach 0.005mm. In the production of series parts, precision surface castings produced by instrumentation, injection molding and other processes can greatly reduce production costs.

Ultra-high performance mineral materials have high heat capacity and a thermal expansion coefficient similar to that of iron, which reduces the thermal impact on machine tools and is conducive to the effective combination of ultra-high strength materials with other components.

| Parameter | Value |

| Thermal Conductivity | 2.7 W/(m*k) |

| Specific Heat Capacity | 1050 J/(kg*k) |

Strong vibration damping performance:

Mineral castings have better vibration damping performance than steel and cast iron, and can effectively absorb and reduce external vibrations.

Good thermal stability:

Machine tools made of mineral castings have high specific heat capacity and low thermal conductivity, ensuring stability.

Self-compacting performance:

The high fluidity of the bonding material gives mineral castings excellent self-compacting properties.

Strong formability:

Mineral materials can be cast into complex shapes and structures, and have good forming capabilities.

Corrosion resistance:

The casting has a dense structure, low permeability, and excellent corrosion resistance.

Energy saving and environmental protection:

Mineral castings do not require further processing after molding, which shortens the production time.

Short delivery cycle to quickly meet customer needs.

Precision manufacturing:

The verticality, flatness and parallelism of mold assembly can reach 0.1mm.

Post-processing such as surface grinding or steel plate milling/drilling can achieve an accuracy of 0.005mm.

Cost-effective production:

The use of instrumentation and injection molding processes in the production of precision castings can significantly reduce production costs.

Thermal stability:

High-performance mineral materials have high heat capacities.

Their coefficient of thermal expansion is similar to that of cast iron, reducing the thermal impact on machine tools.

Effective integration:

The thermal properties of mineral castings enable better integration with ultra-high-strength materials and other components.

Copyright © 2023 Jinan EAST STAR Precision Measure Co., Ltd. All rights reserved. | Sitemap | Privacy Policy | Support By Leadong