Discover Coordinate Measuring Machines

Discover high-quality Coordinate Measuring Machines for precise measurement of work-pieces. Ensure accuracy and reliability with our advanced CVA240 series.

Introduction to Coordinate Measuring Machines

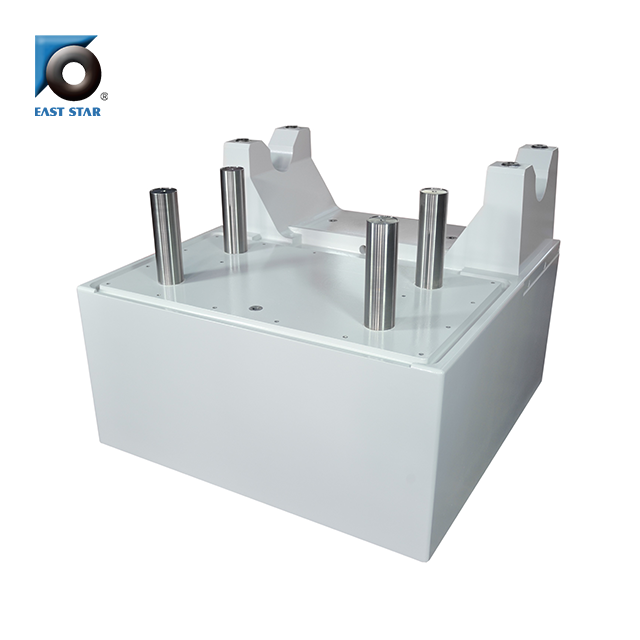

Discover the precision and reliability of EAST STAR Coordinate Measuring Machines (CMMs). Our advanced CMMs, equipped with laser interferometers and electronic levels, ensure high-precision measurements. With real-time online quality monitoring and strict control of processing environments, we guarantee optimal performance and accuracy. Our dedicated team, boasting over a decade of experience, provides unparalleled technical support and after-sales service to meet all your quality control needs.

Explore Key Features of Our Coordinate Measuring Machines

Discover the outstanding features of our Coordinate Measuring Machines (CMMs) that set us apart in the industry. Our CMMs are designed with high precision, exceptional durability, and robust technical support, ensuring they meet the core values of quality and reliability. Explore how these key features can enhance your measurement accuracy and operational efficiency.

High Precision Measurement

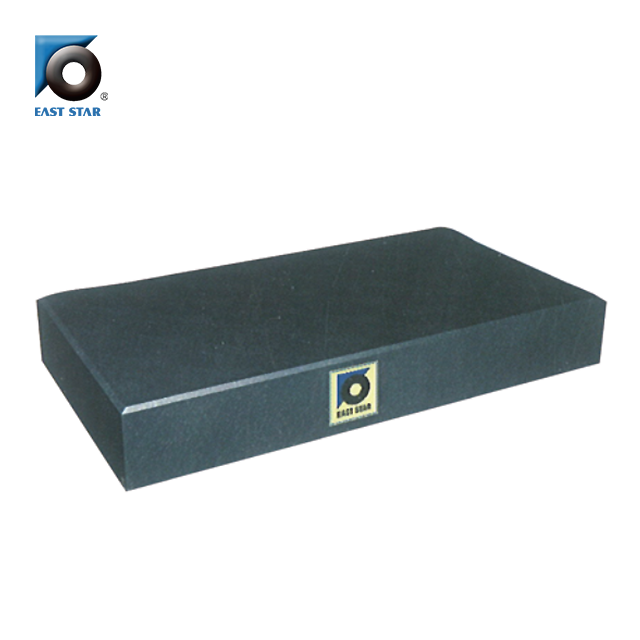

Our CMMs deliver unparalleled measurement accuracy, thanks to their fine crystalline granite material. This ensures stable and precise measurements, crucial for ultra-precision machine tools.

Exceptional Durability

Built from rigorously tested granite, our CMMs offer superior durability. The hard texture of the granite ensures long-lasting performance, making them ideal for demanding inspection tasks.

Comprehensive Technical Support

We provide extensive technical support to ensure optimal use of our CMMs. Our expert team is always ready to assist, ensuring your measurement tools operate at peak performance.

Stable and Reliable Accuracy

Our granite-based CMMs provide high and stable accuracy over time, outperforming cast iron and steel alternatives. This reliability is essential for precision instruments and mechanical parts inspection.

Product Catalog and Specifications of Coordinate Measuring Machines

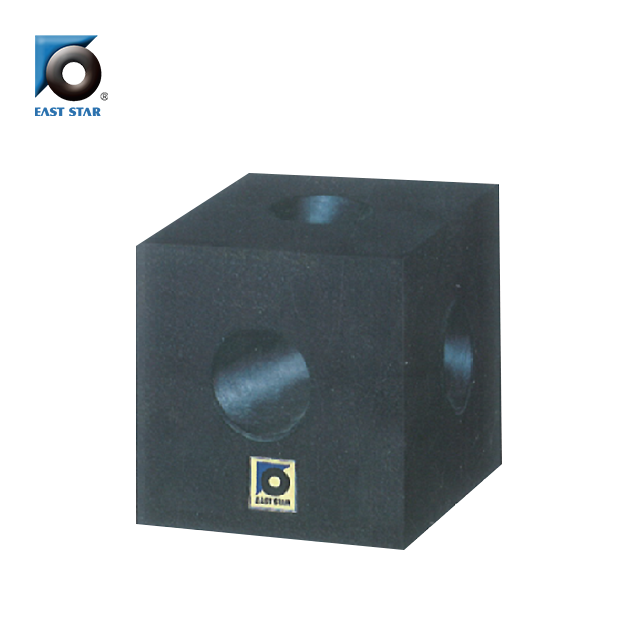

Explore our extensive range of Coordinate Measuring Machines (CMMs), each meticulously designed for precision and reliability. Our CVA240 Series, compatible with dial indicators and electronic probes, ensures accurate dimension inspections. The Granite-M-T Series CVA240 is perfect for relative dimension inspections with gauge blocks. For spindle and squareness measurements, the GB6092-85 CVA235 Series features convenient round holes for easy handling. Our products adhere to ISO 9001 standards, guaranteeing quality and compliance. Detailed specifications and certifications are provided to assist you in making an informed choice.

Hear What Our Customers Say About Our Coordinate Measuring Machines

John Smith

"Our experience with EAST STAR's coordinate measuring machines has been outstanding. The real-time online quality monitoring has significantly boosted our machining efficiency. Their rigorous control over the processing environment ensures top-notch precision every time."

Emily Johnson

"The advanced measuring equipment from EAST STAR, including the laser interferometer and electronic level, has revolutionized our quality control process. Their professional team, with over 10 years of experience, brings unparalleled expertise to the table."

Michael Brown

"EAST STAR's commitment to strict process control and their own laboratory for data analysis support has been a game-changer for us. The ability to trace products through bar codes ensures that we maintain the highest standards of quality."

Sarah Davis

"With EAST STAR's coordinate measuring machines, we have seen a remarkable improvement in our quality assurance. The strict control of the processing environment, maintaining a consistent 21°C and 60% humidity, is crucial for our high-precision needs."

David Wilson

"The precision and reliability of EAST STAR's CMMs are unmatched. Their real-time online detection capabilities allow us to perform CMM detection directly on the machine, significantly enhancing our production workflow."

Jessica Martinez

"EAST STAR's meticulous approach to quality control, from material sampling to process monitoring, ensures that our products meet the highest standards. Their advanced measuring equipment has been instrumental in achieving our quality goals."

Frequently Asked Questions about Coordinate Measuring Machines

Discover answers to common questions about Coordinate Measuring Machines (CMMs) to help you make informed decisions. Our FAQs cover essential information, troubleshooting tips, and best practices to ensure optimal performance and accurate measurements.

A Coordinate Measuring Machine (CMM) is a device used to measure the physical geometrical characteristics of an object. These machines can be operated manually or controlled via computer software. CMMs are essential for ensuring precision in manufacturing and quality control.

Choosing the right CMM depends on factors like the size of the parts to be measured, required accuracy, and specific application needs. Consider consulting our detailed manuals and specifications at www.campbellsci.com for guidance tailored to your requirements.

Start by ensuring your system is well-grounded. Check the voltage of the primary power source and inspect wiring connections for faults. Resetting the data logger can also resolve many issues. For more detailed troubleshooting, visit www.campbellsci.com/troubleshooting.

Calibration frequency depends on usage and specific industry standards. Generally, it's advisable to calibrate your CMM annually. Regular field calibration checks can help maintain accuracy. Refer to our calibration guidelines at www.campbellsci.com/calibration.

Campbell Scientific CMMs are compatible with various software, including LoggerNet and CRBasic Editor. These tools help in programming, data collection, and analysis. For a full list of compatible software, visit www.campbellsci.com/software.

To improve voltage measurement quality, ensure proper grounding, check for loose connections, and inspect cables for damage. Using shielded cables can also reduce noise. Detailed tips are available at www.campbellsci.com/voltage-measurement.

NAN (Not a Number) or INF (Infinity) occurrences usually indicate a measurement or programming error. Check your CRBasic program for logic and syntax errors. Simplifying the program can help identify the issue. More troubleshooting tips are available at www.campbellsci.com/errors.

Resetting the data logger can resolve many issues. To reset, follow the instructions in the LoggerNet software by clicking Connect, then Station Status. Detailed steps are provided at www.campbellsci.com/reset-data-logger.

Video tutorials covering various aspects of CMM usage and troubleshooting are available at www.campbellsci.com/videos. These resources provide step-by-step instructions to help you get the most out of your equipment.

Joining the Campbell Scientific user forum is easy. Visit www.campbellsci.com/forum to sign up and start posting your questions. The forum is a great place to connect with other users and get expert advice.

Request a Quote for Your Coordinate Measuring Machine

Ready to enhance your precision measurement capabilities? Fill out our contact form to request a quote for your ideal Coordinate Measuring Machine. Our team at Jinan EAST STAR Precision Measure Co., Ltd. is here to provide tailored solutions and expert advice. Don't wait—take the first step toward superior accuracy today.

About Our Company and Customization Capabilities

At EAST STAR, we pride ourselves on our unwavering commitment to excellence and customization capabilities. With over a decade of experience, our quality inspectors are equipped with unparalleled skills, ensuring every product meets the highest standards. Our state-of-the-art facilities boast advanced measuring equipment such as laser interferometers, CMMs, and electronic levels, enabling precise and reliable quality control. Our real-time online quality monitoring system allows us to perform CMM detection directly on the machine, significantly enhancing machining efficiency.

Our dedication to precision is further exemplified by our strict control of the processing environment, maintaining a consistent temperature of 21 degrees Celsius and humidity of 60%. Our in-house laboratory rigorously samples and analyzes materials, ensuring optimal quality from the very beginning. Through meticulous process control, we track and monitor each product's progress using barcodes and process control cards, guaranteeing both quality and timely delivery.

EAST STAR's core values revolve around creating value for our customers and continuously striving for excellence. Our ISO 9001 certification and UKAS accreditation are testaments to our rigorous quality control standards and professional capabilities. Trust EAST STAR to deliver customized, high-precision solutions that meet your exact needs.