Tel: +86-531-88917773 E-Mail: eaststar@public.jn.sd.cn

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Product Description

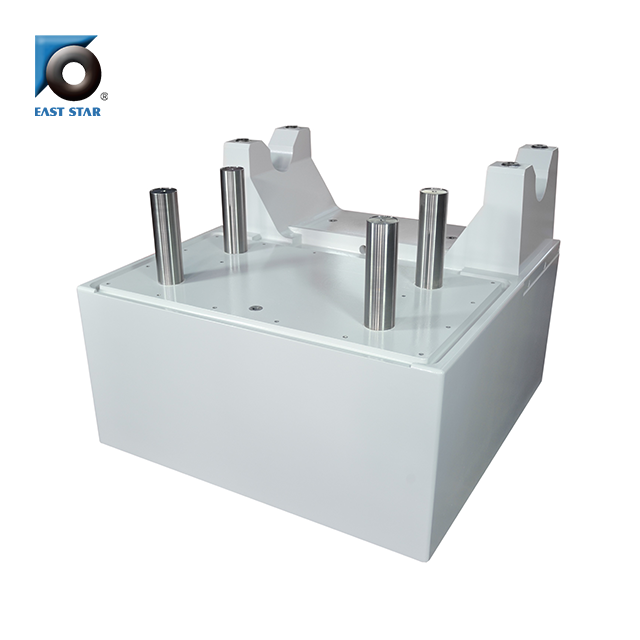

Mineral Casting Custom Components for Industrial Precision are designed for superior performance. These components are ideal for industrial applications requiring high precision.They are made from high-quality mineral casting material. The material provides exceptional thermal stability and vibration damping.

EAST STAR offers reliable solutions tailored to your requirements. These components deliver consistent and efficient performance.

| Parameter | Value |

| Material | Mineral Casting |

| Application | Industrial Precision |

| Thermal Stability | High |

| Vibration Damping | Excellent |

| Customization Available | Yes |

| Manufacturer | EAST STAR |

| Installation | Easy |

| Design | Lightweight |

High Precision

Provides precise dimensions for industrial applications, ensuring reliable performance.

Thermal Stability

Maintains consistent performance at different temperatures.

Vibration Reduction

Effectively reduces vibrations and improves operational stability.

Customizable Designs

Supports custom designs to meet specific industrial needs.

Durable Materials

Made from mineral castings, providing long-lasting performance.

Lightweight Construction

Easy to handle and install in a variety of settings.

Corrosion Resistant

Withstands the effects of chemicals and environmental factors.

Environmentally Friendly Choices

Reduce energy consumption during manufacturing.

Enhanced Stability

Maintains performance under thermal and mechanical stress.

Cost Effectiveness

Provides an affordable alternative to traditional materials.

Low Maintenance

Requires minimal maintenance over its lifecycle.

High Strength to Weight Ratio

Combines durability with lightweight construction.

Increased Precision

Provides consistent precision in industrial operations.

Reduced Noise

Minimizes operating noise with effective vibration damping.

Machinery Bases

Serves as a stable base for precision machinery.

Measuring Instruments

Ensures high accuracy in measuring systems.

Electronic Devices

Provides thermal stability for sensitive components.

Automation Systems

Enhances stability in robotic and automation setups.

1. What are the main advantages of using mineral casting components?

Mineral casting offers thermal stability, vibration damping, lightweight construction, and corrosion resistance. It is also cost-effective and low-maintenance.

2. Can these components be customized?

Yes, EAST STAR offers tailor-made designs to meet specific industrial requirements.

3. Which industries use mineral casting components?

They are widely used in machinery bases, measuring instruments, medical devices, automation systems, and aerospace applications.

4. How does mineral casting compare to traditional materials?

Mineral casting is more stable under temperature fluctuations, provides better vibration damping, and is lighter than many traditional materials such as metals.

5. What sizes and shapes are available?

EAST STAR offers customizable shapes and sizes to suit different applications.

Product Description

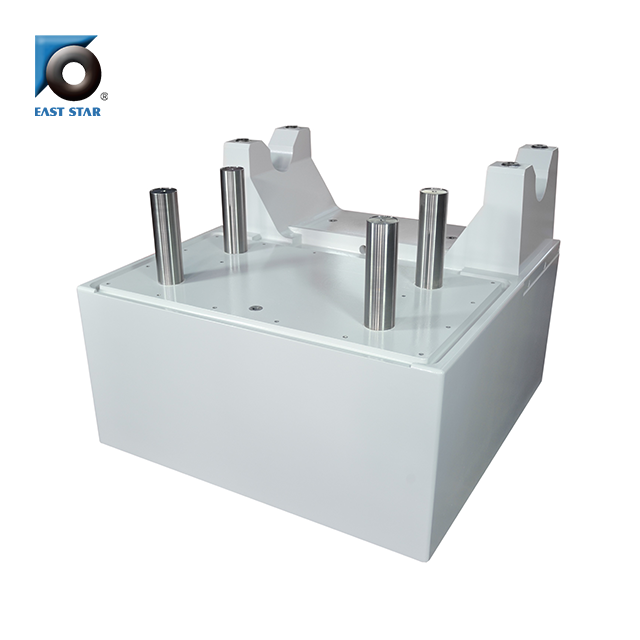

Mineral Casting Custom Components for Industrial Precision are designed for superior performance. These components are ideal for industrial applications requiring high precision.They are made from high-quality mineral casting material. The material provides exceptional thermal stability and vibration damping.

EAST STAR offers reliable solutions tailored to your requirements. These components deliver consistent and efficient performance.

| Parameter | Value |

| Material | Mineral Casting |

| Application | Industrial Precision |

| Thermal Stability | High |

| Vibration Damping | Excellent |

| Customization Available | Yes |

| Manufacturer | EAST STAR |

| Installation | Easy |

| Design | Lightweight |

High Precision

Provides precise dimensions for industrial applications, ensuring reliable performance.

Thermal Stability

Maintains consistent performance at different temperatures.

Vibration Reduction

Effectively reduces vibrations and improves operational stability.

Customizable Designs

Supports custom designs to meet specific industrial needs.

Durable Materials

Made from mineral castings, providing long-lasting performance.

Lightweight Construction

Easy to handle and install in a variety of settings.

Corrosion Resistant

Withstands the effects of chemicals and environmental factors.

Environmentally Friendly Choices

Reduce energy consumption during manufacturing.

Enhanced Stability

Maintains performance under thermal and mechanical stress.

Cost Effectiveness

Provides an affordable alternative to traditional materials.

Low Maintenance

Requires minimal maintenance over its lifecycle.

High Strength to Weight Ratio

Combines durability with lightweight construction.

Increased Precision

Provides consistent precision in industrial operations.

Reduced Noise

Minimizes operating noise with effective vibration damping.

Machinery Bases

Serves as a stable base for precision machinery.

Measuring Instruments

Ensures high accuracy in measuring systems.

Electronic Devices

Provides thermal stability for sensitive components.

Automation Systems

Enhances stability in robotic and automation setups.

1. What are the main advantages of using mineral casting components?

Mineral casting offers thermal stability, vibration damping, lightweight construction, and corrosion resistance. It is also cost-effective and low-maintenance.

2. Can these components be customized?

Yes, EAST STAR offers tailor-made designs to meet specific industrial requirements.

3. Which industries use mineral casting components?

They are widely used in machinery bases, measuring instruments, medical devices, automation systems, and aerospace applications.

4. How does mineral casting compare to traditional materials?

Mineral casting is more stable under temperature fluctuations, provides better vibration damping, and is lighter than many traditional materials such as metals.

5. What sizes and shapes are available?

EAST STAR offers customizable shapes and sizes to suit different applications.

Copyright © 2023 Jinan EAST STAR Precision Measure Co., Ltd. All rights reserved. | Sitemap | Privacy Policy | Support By Leadong